The Out of hand: Materialising the digital display in Sydney, showcases over 60 designers, artists and scientists works which span across 7 main concepts or themes. When identifying these themes it becomes apparent which artworks cohere to one or more. These themes include ‘Analog to Post-digital, Modelling Nature, New Geometries, Rebooting Revivals, Pattern as structure, Remixing the figure and process.’ Anatomic’s Pty Ltd Acrylic Custom Cranial Implant made in 2016, stood out as an important transition in 3D printing in regards to its function.

The Acrylic Custom Cranial Implant is used as a supplementary bone structure to restore the shape of the bone that has been lost during severe trauma to the skull. Cranioplasty is a very dangerous and challenging procedure, with the introduction of 3D printing technologies the success rate of harvesting a compatible bone graft has increased significantly within patients when exploring the history of Cranioplasty to 3D printing.

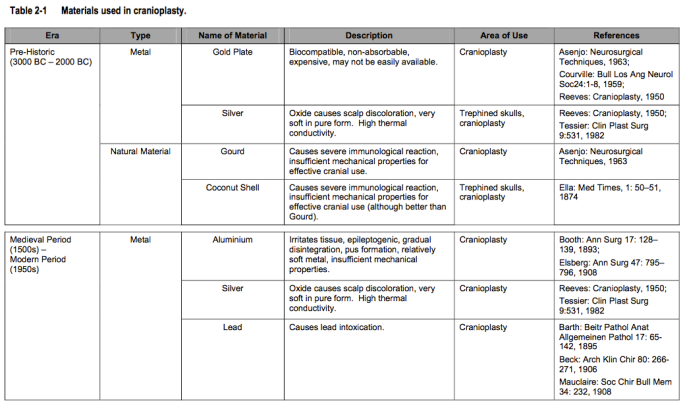

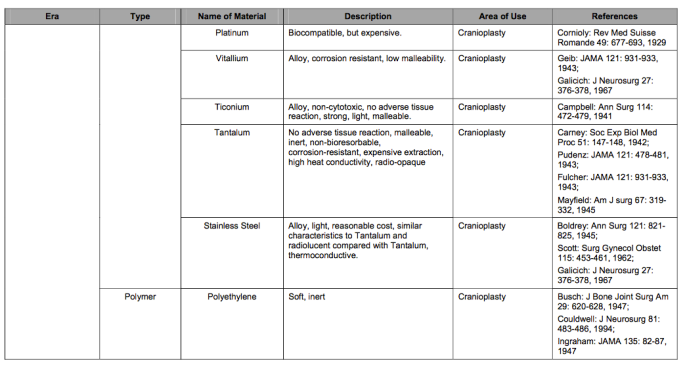

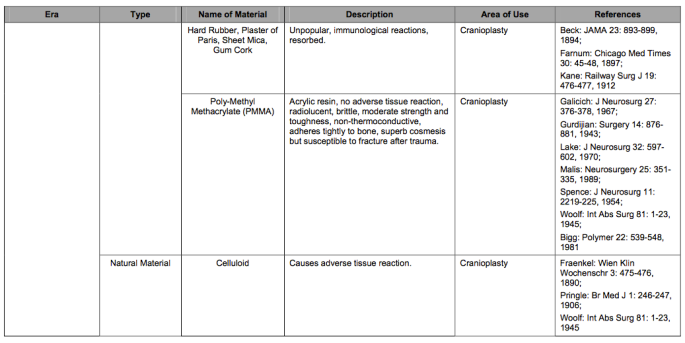

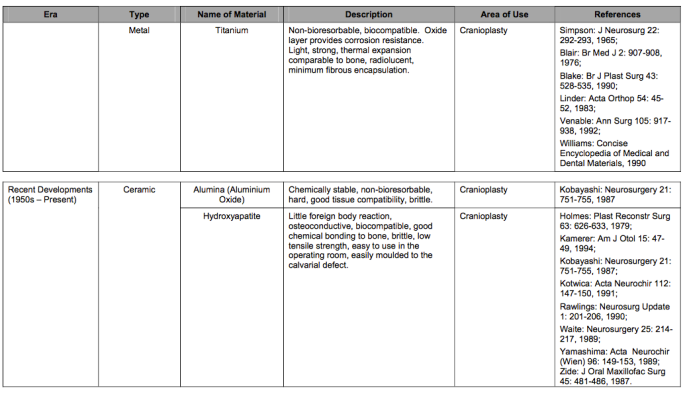

Cranioplasty’s history can be traced to Incas in Peru and Celtic tribes in Europe during prehistoric time who operated on the cranium bone with gold, silver and Gourds as a supplementary bone structure. In the late “19th century and early 20th century significant advances were made in cranioplasty with several clinical and experimental reports on the surgical techniques and materials used. Autografts, as well as various metallic bone substitute materials, gained increasing popularity.” During the 1940s, the material methylmethacrylate (bone cement) was introduced, which is still used today in hip and knee replacements, however the issue of having to remove the implants after a number of years was still an issue until the mid 1990’s when biodegradable materials were used as ‘structural fixation until healing occurred.’

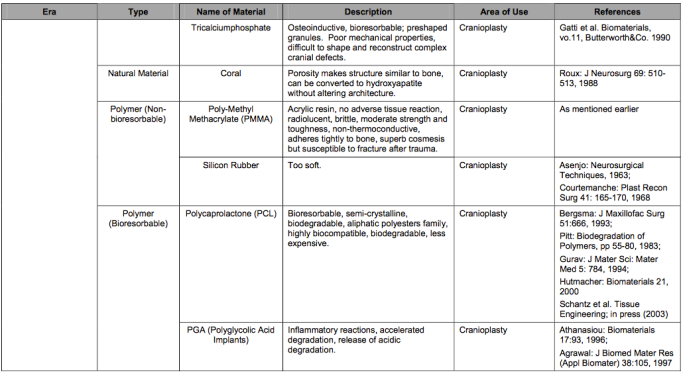

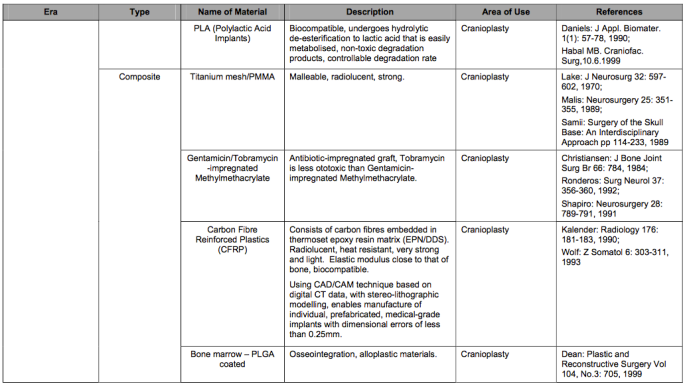

Below is a table taken from Jant Schantz, 2004, literature review, which shows the era of what materials were used in Crainoplasty.

3D printing has changed Cranioplasty significantly, improving surgery time, reducing the risk of infection, reduction in cost and the surgery is deemed less invasive. The biggest improvement however is the ‘fit’ of the pre-made cranial implant. This eliminates the problem prior to the introduction of 3D printing when the surgery had to be performed every couple of years etc. Todays advancements also ensure that if a procedure has to be repeated post-procedure, that surgeons can get in and out efficiently.

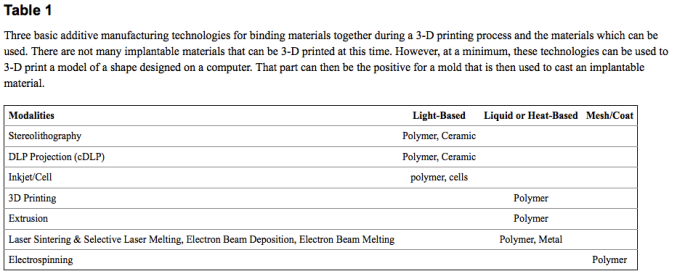

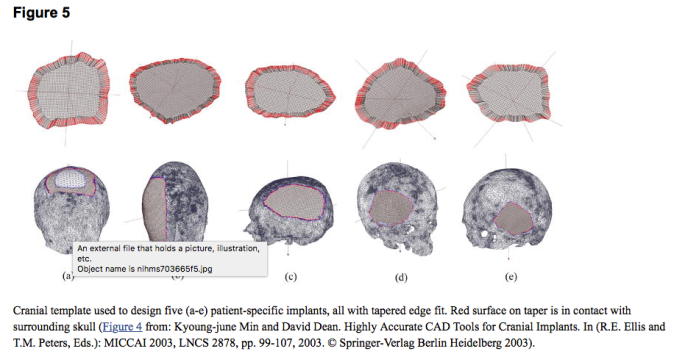

After many different techniques and materials in the production of 3D printing, internal pore geometry was created which assists and promotes cell growth between the implant and the brain. This means that the new supplementary bone (cranium implant) will resorb in the old bones place and become a stronger bone structure. Computer aided software can also scan the brain and overlap the existing skull to produce an image which designs the best shape and place for the implant to be attached to the patients skull, (please see below table and figure) this allows a greater rate of compatibility as well as lowers risk for the patient.

Below is the 3D printed AnatomicsAcrylic Custom Cranial Implant model on display at the Out of Hand exhibition. 3D printing is described as an ‘additive process’ in which the object is created by adding layers

A skull phantom and mold are created with computer software to assist in the 3D printing procedure and interchanged with the 3D printer, the mold that is printed on the polyjet printer is then used to shape the acrylic implant.

Scott Crump developed the first FDM printer, a model that is used by most businesses in regards to 3D printing today. Crump then founded Stratasys which supplies 3D printers and from there. In 2000 the ‘Inkjet’ 3D printer was introduced to the market which is what this cranial implant was printed on.

“PolyJet 3D printing is similar to inkjet document printing. But instead of jetting drops of ink onto paper, PolyJet 3D printers jet layers of liquid photopolymer onto a build tray and cure them with UV light. The layers build up one at a time to create a 3D model or prototype.”

The acrylic cranial implant, stemmed from the worlds first surgical removal by Ralph Mobbs in 2015 of two cancerous vertebrae. The reattached patient’s skull to their spinal column was high risk but made possible with a specific titanium implant made by anatomic’s.

This advanced them into using varied materials such as titanium, acrylic and now a porous polyethylene to decrease risk and enhance surgery. These materials were experimented on cranial, facial, chest, orthopaedic implants as well as other skeletal and soft tissue parts. Using the CT scans and 3D printing methods, surgical biomodels such as bone harvest templates, implant positioning templates were critical in decision making and planning.

Anatomic’s is a company based in Melbourne which has been in the manufacturing and surgical marketing business since 1996. Anatomic’s assists in the design and printing of the 3D cranial implant as well as many other surgical products, working with customers such as Neurosurgeons, plastic & reconstructive surgeons, oral & Maxillofacial surgeons, orthopaedic surgeons, ENT surgeons and Thoracic surgeons.

First a CT scan is taken of the brain to display “images of internal organs, bones, soft tissue and blood vessels.” The CT scan is also sent to Anatomic’s to provide measurements of the brain and skull to accurately design a cranial implant that will fit, the CT scan is a key component in providing them with a model they can work off when beginning to print the patient specific implant, “The cross-sectional images generated during a CT scan can be reformatted in multiple planes, and can even generate three-dimensional images.’ After the CT scan is sent to Anatomic’s, a scheduled meeting will take place using Anatomic’sC3D to discuss the patient and the implants design, function and fit with leading surgeons.

First a prototype is produced in collaboration with Anatomic’s and surgeons from the original CT scan which assists pre surgery preparation, this prototype allows for experimentation and testing to deem whether the implant will fit or have to be rescaled etc. A second CT scan is then taken of the BRT (Bone resection template) to guide surgeons in the procedure to follow during surgery, during this stage a Biomodel is also created to re-test the fit of the cranial implant on the specific patient. This process experience is key in breaking down barriers between surgeons, engineers and patients to identify what needs to be done from all angles. The collaborative program adds to the precision and compatibility to ensure that the process has eliminated risks from all angles.

The Acrylic used in the Custom Cranial implant is clear plastic, used as a shatterproof replacement for glass, “it’s a synthetic resin produced from the polymerization of methyl methacrylate.” PMMA undergoes particular strengthening procedures which is crucial in ensuring that the overall strength of the implant, made from synthetic resin, can endure lifetime fixture and durability.

“In modern production it is obtained principally from propylene, a compound refined from the lighter fractions of crude oil. Propylene and benzene are reacted together to form cumene, or isopropylbenzene; the cumene is oxidized to cumene hydroperoxide, which is treated with acid to form acetone; the acetone is in turn converted in a three-step process to methyl methacrylate (CH2=C[CH3]CO2CH3), a flammable liquid. Methyl methacrylate, in bulk liquid form or suspended as fine droplets in water, is polymerized (its molecules linked together in large numbers) under the influence of free-radical initiators to form solid PMMA.”- Taken from Britannica

With its glass like appearance, the Acrylic implant allows the surgeon to see if there is a collection of fluid or a haematoma forming in the extra-dural space in the brain. Pre-drilled fixation, dural suture, fluid transfer, and temporalis muscle suture holes are pre-drilled to minimise operating theatre time which is one of the main reasons acrylic is specifically used today. Through the history of materials used to make implants, acrylic lowers risks and allows surgeons to see problems before it becomes catastrophic. The predrilled holes in the cranial implant allows for fluid transfer and easy attachment during surgery.

In short during the Cranioplasty procedure surgeons will make a small incision in the scalp and begins to clean the area for implantation. The implant will be attached using screws and the area may be drained of fluid. The area is then stitched back up.

Cranioplasty today is extremely efficient, Anatomic’s states the benefits of using acrylics are that there is Clear vision through the implant, it is Ready-to-use, it is CT and MRI compatible, Simple removal and it Beats Mixing with “No need for cutting, shaping or mixing during surgery. This eliminates the risk of monomer release and damage of dural and sub-dural tissues associated with exothermic reaction during in situ preparation of an implant.”

3D Printing machines, were once expensive, but as they are becoming more and more popular, it has lowered the cost and increased production and manufacturing rates as well as created new potential. Already we are seeing scientists and engineers working together to produce 3D printed living tissue that can be deposited into the 3d printer and printed. This adds to the uncapped potential of what 3D printers can achieve. For instance, 3D printed living heart valves are being tested on in many medical centres. Bio-printing, could eliminate the shortage of donors and increase lives saved. (It is said that on average 21 people die per day because they don’t have a compatible donor) Through bio-printing patient specific living cells, scientists and surgeons will eventually be able to structure a living organ that can be implanted into the patients body with 100% compatibility without having to worry about the risks around incompatibility.

During my visit to the Out of Hand excursion, there were many different artworks which spoke to each other in different ways, there were many interactive ones that added to process and others that added to the experience of the artwork and themes being discussed, however the Cranial implant stood out to me the most due to its cutting edge design and such a huge advancement of 3D printing in the medical world today. Within DIGC310, one of my classes this semester, I have been using Tinkercad to 3D mock a game board piece which uses light as its mechanic. The use of 3D printing in the medical world grabbed my attention as something worthy of advancement and research. Encased in a box added to the idea of its importance within Cranioplasty and medicine. Although I would of loved to of picked it up and interacted with it in some form, just seeing it and knowing that it was designed using a 3D printer was enough of a feature as I became more inclined to study the way in which it performed and the materials they used. With a brief understanding of how 3D mocking works, 3D scanning added an entirely new element for me to think about in which you could produce and print a specific implant to match a specific patients skull which saves a lot of time in regards to correcting measurements on the 3D software.

Overall 3D printing is becoming more and more popular, it has lowered the cost and increased production and manufacturing rates as well as created new potential especially in regards to Bio-printing in the near future within the medical world. It has changed the way surgeons perform and enhanced the success rate of the procedure undertaken during Cranioplasty. With a collaborative program introduced by Anatomic’s, the 3D printing process becomes smoother as well as ensuring that all angles of the design increase compatibility for the specific patient. The printing of the Acrylic implant has overall managed to reduce surgery time and improve visibility for the surgeon through the acrylic used and the way the implant has been designed to “fit.” The Polyjet 3D printer is extremely important, not only in regards to medical advancements but also for patients who may eventually have to go through the surgery in the near future.